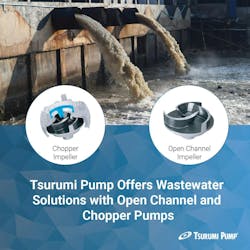

Tsurumi Pump Offers Wastewater Solutions with Open Channel and Chopper Pumps

By Ashleigh Johnson

As wastewater challenges continue to evolve, users need dependable pumping solutions that can adapt to demanding conditions. Tsurumi Pump provides a robust lineup of open channel and chopper pumps, engineered to handle specific wastewater conditions while minimizing downtime and clogging. Whether the need is high flow or heavy duty cutting, Tsurumi’s wastewater solutions mitigate challenges to keep operations flowing.

Open Channel Pumps: High Flow, Low Clog Risk

Tsurumi’s open channel pumps are designed to move wastewater with large solids content such as rags and plastics. Engineered with wide-passage impellers, open channel pumps allow debris to pass through, thereby minimizing blockages. The hydraulic design features an axial impeller adjustment system that maintains performance while reducing energy usage over time.

For dry-pit installations, wastewater treatment plants, and lift stations, open channel pumps deliver high flow rates and low shear, preventing the early breakdown of solids. Open channel pumps do not chop or grind solids, therefore they are most effective in applications where solids are relatively soft or have been pre-screened. High flow municipal stations often prefer open channel pumps due to their reliable design and ease of access.

The moving parts of Tsurumi’s open channel pumps operate with minimal exposure to solids; in turn, this reduces wear and simplifies the maintenance process. When inspecting an open channel pump, it is recommended that users check impeller wear, bearing condition, seal integrity, and pump alignment.

Chopper Pumps: Cutting Power for Tough Waste

Featuring a heavy-duty cutting system, chopper pumps macerate challenging solids and fibrous waste into small pieces. The rotating and stationary cutters, in combination with high torque, ensure reliable chopping while providing continuous flow. This leads to a reduced risk of clogging, ultimately prolonging pump life.

Chopper pumps are often installed in submerged applications where vertical space is limited, such as sumps or wet wells. When submerged, a chopper pump may require a lifting mechanism, impacting operational continuity.

Because of the cutting components and submersible nature, chopper pumps require increased maintenance compared to open channel pumps. When completing inspections, users should focus on cutter sharpness, clearance between cutters and wear plates, motor condition, and condition monitoring of submersible seals and bearings.

The Changing Demands of Wastewater

From chemical composition of wastewater to physical site constraints, the choice between open channel and chopper pumps is seldom a one-size-fits-all decision. Critical factors such as solid make up, accessibility, abrasion, flow rate, head, corrosion resistance, etc. aid in the decision for the best fitting pump. With increasing solid and fibrous content in wastewater streams, selecting the right pump is essential to balance investment, operational reliability, lifecycle cost, and compliance needs.

Ashleigh Johnson is municipal engineer, Tsurumi Pump