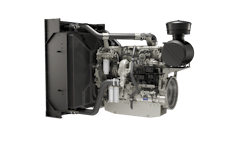

New Perkins 2806J-E18TAG1 Expands EU Stage V Offering

Building on its already comprehensive EU Stage V power offering, Perkins is announcing a new addition to the range – the 2806J-E18TAG1 ElectropaK. With more than 90 years of design experience and more than 3 million Perkins-powered generator sets operating around the world, Perkins understands the needs of the power generation industry. This knowledge and expertise has driven the design and development of the 2806J-E18TAG1, a new engine that delivers a powerful package and ease of integration to meet the requirements of the electric power sector.

By achieving ISO 8528-5 G2 performance, the 2806J – which is available to order – provides excellent load acceptance in a wide range of electric power applications. From a stationary prime source of power to a mobile unit serving the rental sector, the 2806J performs seamlessly, generating dependable power for everything from jobsites to critical installations including hospitals and data centers.

Keeping the power on

“Reliable electric power is not an option, it’s a fundamental need to keep operations running, whether that’s for standby when the main power fails to meet onsite prime power requirements,” said Jaz Gill, vice president of global sales, marketing, service and parts. “Our engines are engineered and expertly crafted to provide reliable, stable and sustainable power for our customers, with the new 2806J being the latest in a long line of products that also deliver a low total cost of ownership.”

For generator manufacturers and end users looking to reduce their greenhouse gas emissions, the 2806J can, subject to the fuel used meeting Perkins’ fuel specifications*, run with biodiesel up to B20 based on a 20 percent dilution of biodiesel with standard diesel or on 100 percent hydrotreated vegetable oil (HVO).

Connectivity solutions to help generator set end users maximize their investments

The 2806J produces up to 610 kVA at 50 Hz and is switchable to 60 Hz, delivering up to 625 kVA. The ElectropaK features the latest electronics with a single, on-engine electronic control module (ECM) that simplifies wiring harnesses, eases installation, supports future diagnostics and is fully capable of integration with customers’ telematics solutions. The ECM also manages all aspects of aftertreatment operation and regeneration without operator input. Regeneration occurs automatically with no impact to performance, maximizing uptime.

Additionally, Perkins offers a powerful and growing portfolio of connectivity solutions that can help promote the optimal performance of diesel engines. Available as a standalone service from Perkins or easily integrated with generator equipment manufacturers’ offerings, connected engine capabilities deliver timely insights through a customizable dashboard of performance, fuel and oil consumption, and other vital engine data points that assist in maximizing the uptime of Perkins-powered equipment.

These connectivity offerings are integrated with expert maintenance and service capabilities from the Perkins global distributor network to prompt the proactive diagnosis and resolution of engine issues, helping technicians provide solutions and minimize downtime and repair expenses.

The new 2806J-E18TAG1 joins the Perkins full lineup of Stage V certified engines for electric power generation: 400 Series, 904 Series, 1200 Series, 1700 Series, and the 2000 Series, with power ranging from 4 kW @ 1500 rpm to 559 kW @ 1500 rpm.

As with all Perkins engines, the new 2806J is supported by a global support network of 88 distributors covering 185 countries, ensuring stable and sustainable electric power when customers need it, where they need it and how they need it.

* Fuels must meet the specifications and characteristics described on www.perkins.com in order to be used in Perkins engines and reduce the risk of downtime.

About the Author

Michael Roth

Editor

Michael Roth has covered the equipment rental industry full time for RER since 1989 and has served as the magazine’s editor in chief since 1994. He has nearly 30 years experience as a professional journalist. Roth has visited hundreds of rental centers and industry manufacturers, written hundreds of feature stories for RER and thousands of news stories for the magazine and its electronic newsletter RER Reports. Roth has interviewed leading executives for most of the industry’s largest rental companies and manufacturers as well as hundreds of smaller independent companies. He has visited with and reported on rental companies and manufacturers in Europe, Central America and Asia as well as Mexico, Canada and the United States. Roth was co-founder of RER Reports, the industry’s first weekly newsletter, which began as a fax newsletter in 1996, and later became an online newsletter. Roth has spoken at conventions sponsored by the American Rental Association, Associated Equipment Distributors, California Rental Association and other industry events and has spoken before industry groups in several countries. He lives and works in Los Angeles when he’s not traveling to cover industry events.